Business Value of Knowledge Management Systems

We may receive compensation from partners and advertisers whose products appear here. Compensation may impact where products are placed on our site, but editorial opinions, scores, and reviews are independent from, and never influenced by, any advertiser or partner.

One of my first jobs was as a sales assistant in a small clothing store in my hometown. At the age of 16, I was told that I would be required to stay until 10 p.m. on the last Saturday of every month to help count the store's inventory.

At first, I was pretty excited to be involved in such a "grown-up" task, and I envisioned myself scanning barcodes and being in charge of my own section. That was until I was presented with a clipboard of paper and a pen and told to count thousands of pieces of inventory — by hand.

Of course, the store's headquarters regularly complained that the numbers didn't add up and that we'd need to recount all of the current stock. This occurred every month without fail.

The store no longer exists, but the memory of terrible inventory management lives on. The moral of the story? A good inventory management system is truly the backbone of a successful business.

In this article, we'll go through four inventory management systems that small businesses can use to make sure they don't meet the same fate as my first employer.

Overview: What is inventory management?

Inventory management refers to how a business manages its current stock, including how it tracks and manages the number of products as they move in, across, and out of the business.

It encompasses making sure the right levels and quantities of stock are available at the right time and in the correct locations. It can also involve processes such as optimizing warehouse layouts and identifying redundant inventory.

Inventory management is different from inventory control, which focuses more on the processes involved in purchasing, shipping, and storing inventory.

Inventory control also means tracking movement to help identify under-performing products to prevent you from ordering and storing stock you don't need, and, likewise, identifying fast-selling products that require more frequent replenishment so you don't run out.

4 types of inventory management systems

Although there are four main types of inventory management systems, they're not mutually exclusive. Small businesses can use a combination of systems depending on the business type, operation, and size.

Type 1: Periodic inventory management

Instead of tracking inventory on a daily basis, a periodic inventory system tracks inventory at the end of an accounting period. This can be on a weekly, monthly, quarterly, or annual basis.

The system does not require inventory management software. Instead, all inventory is counted physically by hand and manually recorded in journal entries.

Working out the Cost of Goods Sold (COGS) using the periodic inventory system is very straightforward and looks like this:

COGS = Beginning Inventory + Inventory Purchases – Ending Inventory

Periodic inventory systems are typically used by businesses that sell a low volume of items and don't require a highly accurate picture of their inventory levels. For example, a jewelry store that sells a small amount of high-value items would use the periodic system since stock levels are easy to record and track.

Perpetual vs. periodic inventory systems: The main difference comes down to timing. Source: Community Tax.

The advantage of using a periodic inventory management system is that it's very simple to implement and keep track of. This makes it ideal for small businesses that don't keep large amounts of inventory.

However, it can be a burdensome system for larger businesses that run with greater amounts of stock because of a higher probability of inaccuracies. Periodic systems notoriously don't have a great track record of being able to identify mistakes and inventory shrinkage stemming from loss, theft, and damages.

Since everything is recorded by hand, a periodic inventory management system also doesn't provide up-to-date stock and inventory levels.

Type 2: Perpetual inventory management

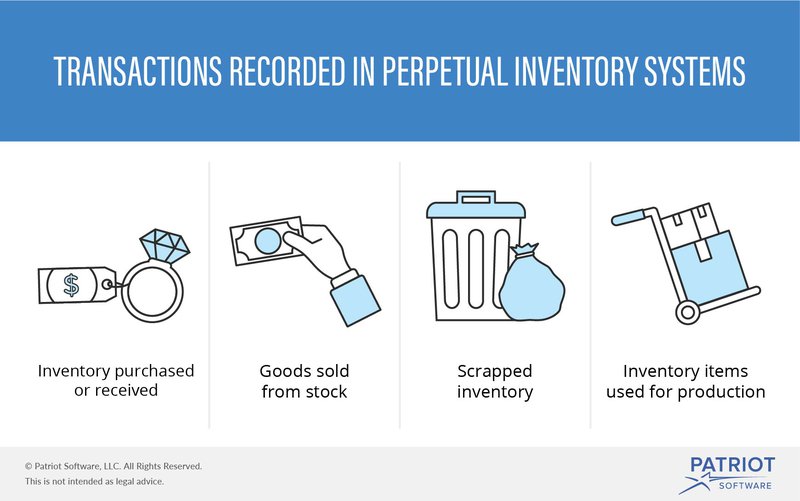

Perpetual inventory management systems track inventory on a continual basis. This means that updates are automatically made to inventory levels when items are bought and new inventory is received, and purchases and returns are instantly recorded in your inventory accounts.

To use the perpetual system, businesses need to use software, usually inventory management software or a POS system.

The main benefits of using a perpetual inventory management system include having an accurate and up-to-date view of inventory levels that enable businesses to order the right amounts of stock and not needing to create closing entries.

Multiple transactions are recorded using the perpetual inventory management system. Source: Patriot Software.

Perpetual inventory systems are typically used by larger businesses and those with a large number of inventory units. Generally, a physical inventory count is still required once a year to check real inventory levels against those recorded by the software.

The downside of this method is that it requires investment in technology and software to carry it out correctly. However, for businesses with high levels of inventory, spending on an inventory tracking system is an investment that will help things run smoothly and save time on manual tracking.

Type 3: Barcode inventory system

Barcode inventory systems use numbers to identify each product being sold. The barcode numbers can represent several different pieces of information related to the item, including the supplier and manufacturer, location of the product, weight, the amount of each item in stock, and so on.

There are two main types of barcode:

- Universal Product Code (UPC): The UPC includes the manufacturer code and a product code. These codes are coordinated through an organization called GS1 (global standard) and are unique codes associated with specific items.

- Stock Keeping Unit (SKU): Individual retailers create their own SKUs to be used for their own internal stock control. SKUs can contain much more information than standard UPCs, including store location, department, item category, size, and color.

Barcode inventory systems are associated with perpetual inventory counts. When each product is purchased, sold, or moved, its respective barcode can be scanned into inventory software, which then automatically updates inventory levels and information.

For businesses with relatively few inventory items, the cost of barcode inventory hardware and software may not be justified.

However, for businesses with large inventory levels, barcode inventory systems can be a welcome addition since they help reduce errors made by manual systems and help capture the most accurate and timely inventory data.

Type 4: Radio frequency identification (RFID) systems

RFID is a technology that uses radio waves between a tag (a tiny microchip) and a reading device. The reader reads data from the tag, which usually includes an identifying inventory number or product-related information such as stock and batch numbers and production dates.

In essence, RFID inventory systems take barcode systems one step further. They are capable of reading tags from 40 feet away and don't require line-of-sight scanning. This makes RFID systems a good choice for businesses that operate warehouses or distribution centers with large amounts of stock and utilize multi-level storage.

These systems often require a significant investment in equipment and technology. RFID tags cost a lot more than regular barcode labels and require specific readers.

Decide which inventory management system is right for your business

There's no rule dictating which type of inventory management system you should choose, but you do need to make sure that whichever you choose, it's helping rather than hindering you to correctly track inventory.

If you're handling large amounts of inventory, you don't need to handle such an important task manually. Inventory management software helps streamline and automate inventory management and inventory control processes so that you can focus on the bigger picture.

Likewise, if you're selling a handful of items per month, or if physical inventory isn't your main source of business, the periodic system might be a good match.

Don't forget to choose the right type of inventory costing method to complement your choice of inventory management system.

The Motley Fool has a Disclosure Policy. The Author and/or The Motley Fool may have an interest in companies mentioned.

Business Value of Knowledge Management Systems

Source: https://www.fool.com/the-blueprint/inventory-management-types/